OSB - oriented strand board. The material is relatively new, but already actively used in construction and decoration.

finishing with osb slabs. A photo

Pros and cons of OSB boards

As virtues This material has the following features:

There are some negative points, but they are much less:

- some manufacturers do not comply with environmental requirements, which leads to an increased release of harmful substances;

- the material is characterized by poor moisture permeability and vapor permeability, so good ventilation is required in rooms with such a finish.

OSB board. Video

OSB finishing process

Often, rough wall cladding with OSB boards is required. This choice of material is explained by the fact that the significant dimensions of the sheets make it possible to reduce the number of joints. When installing OSB boards on a wall, a number of details must be taken into account.

The fixing of the plates is carried out so that joint was located in the middle. A gap of about four millimeters is left between adjacent elements, which will compensate for the expansion of the material.

The OSB sheet hides the bottom strapping frame structure. The top trim is also hidden, and the top side of the plate is aligned with the edge of the trim. In the case of a two-story building, it would be useful to install OSB boards on the wall so that they go into the racks of both the lower and upper floors. This will make the structure more rigid.

It is better to draw a window opening in a building with two floors with a whole sheet, i.e. cut a hole in it for a window. As a result, the joints are carried out to adjacent racks.

To make the rough sheathing with OSB plates more convenient and reliable, it is worth creating additional jumpers in the frame. They can be placed both horizontally and vertically.

For fastening, self-tapping screws or spiral nails are used, having a length of five centimeters and a diameter of four and a half millimeters. These two mounting options can be easily combined.

Basic rules for fastening OSB:

wall decoration with osb slabs. A photo

It is also possible to finish the walls with OSB boards. Since they are quite rigid, it becomes possible to smooth out irregularities. Drywall is a more flexible material and often repeats such irregularities.

OSB for internal partitions

A popular option for interior wall decoration with OSB boards is complemented by the arrangement of interior walls and partitions made of this material. Since it is durable and easy to install, there are many possibilities for transforming the space.

Sheets can be attached to a wooden frame or on metal profile like drywall. But OSB differs in this case from drywall, since it does not deform under its own weight. This weight is very small, so it does not exert a significant load on the frame. Due to the strength and density of the plates, cracks or punching of fasteners can be avoided during installation.

How to finish walls from OSB?

The structure of oriented strand boards is pronounced wooden, which makes them especially decorative. You can finish the surface of such walls with a variety of materials.

The peculiarity of OSB panels is that they are impregnated with wax, paraffin or any resins. The result is a smooth surface. The difficulty of finishing lies in the fact that the finishing material is difficult to connect with such a slippery surface. In addition, impregnating substances are able to come to the surface through the finishing layer. It will help to avoid such troubles. primer coat. After the primer has dried, you can continue finishing with the selected material.

How to finish the floor from OSB?

To finish the OSB floor, you can use varnish, paint or any floor covering.

Lacquering

The OSB surface should be as smooth as possible. If there is roughness, then it should be sanded. An unpolished slab will not be convenient to use and will lose its aesthetics faster. After the leveling process, the floor surface is cleaned of dust and dirt, degreased and primed.

Grinding is not needed if laminated OSB sheets were used for flooring.

Lacquer is applied in stages, in several layers. Colorless transparent formulations or having a color tint can be used.

The disadvantage of the lacquered coating is its sensitivity to synthetic detergents. For cleaning, you will need to use special compounds. In addition, scratches often appear on such a surface.

OSB floor painting

Paint is one of the most budget options for finishing an OSB floor. Often, oil paint is chosen for such purposes, creating a reliable and environmentally friendly coating that is permeable to steam and air.

First, the surface of the plates is puttied, which allows you to hide irregularities. After applying the putty, grinding is performed, which allows you to get a smooth surface.

The next step is to apply a primer, which provides a more even application of paint. The paint is directly applied with a roller in two layers. In order not to make a mistake with the shade and check the interaction of the paint with the base, it is first applied to a small area.

OSB flooring installation

The third option for finishing the OSB floor is laying the flooring. It can be parquet or laminate, linoleum, tile or other finishes. The base needs to be prepared. To do this, all expansion joints are filled with sealant and sanded.

If only one sufficiently thick OSB slab is used as the basis, then the logs are laid at a distance of thirty or forty centimeters.

A more rational option for creating a base for coating is to use relatively thin sheets, about a centimeter thick. They are placed in two layers, the upper perpendicular to the lower. Gluing with parquet glue or fixing sheets with self-tapping screws will help to avoid horizontal displacements.

In order to prepare a wall covered with OSB for painting, the sequence of layers should be as follows:

- do we apply a thick layer? 3 mm. Suitable Ceresit ST 85 PRO or a cheaper analogue of companies such as Master, Moment (but keep in mind that they are less elastic);

- we press into the mesh for facade (density 160 g / m3);

- the next day we apply another layer of glue up to 1 mm thick in order to level the surface along the grid;

- we putty the surface with a universal gypsum putty, for example, Multi Finish or an analogue (for example, Knauf HP Finish - it is a little cheaper);

- paint with water-based paint.

If something is glued on OSB, then it is better not to have fiber panels, but drywall.

Well, and yet, after all, I advise you to consider the option of wall cladding from the inside with a wooden clapboard. It will not take up much space (the thickness is only 1.5-1.6 cm). Then it can be covered with a white stain, then the tree will be protected from various microorganisms, the structure of the tree will remain visible, and at the same time the walls will have a beautiful white tint. For the money, such wall cladding will definitely cost less.

OSB boards for indoor house

Vladimir28.11.2009 15:36 Is it possible to apply plaster and wallpaper on the OSB wall? Vladimir11.12.2009 16:35 You can glue it, but there is no plaster. After all, these plates have zero hygroscopicity, which means they simply won’t hold on ... Zharok07.01.2010 01:53 wooden house can? Vitaliy 10/15/2010 23:23 Hello, in the store they convince me to sheath the house from the outside and inside with moisture-resistant plywood, arguing that plywood has better performance than OSB in terms of hydroscopicity and at a cheaper price. What can you say about this? elena05.11.2010 13:29 Can wall cork be glued on osb 3? Mikhail11.11.2010 15:08 Is it possible to putty OSB after applying the penetration primer? How to glue the wallpaper (Is it necessary to pre-treat the surface and what kind?) Zoya14.03.2011 09:21 Can the walls of a log house sheathed with OSB boards be primed and then puttied for touch-up Alexander 04.04.2011 16:06 I have extensive experience in using these boards. In particular, after puttying with acrylic putty and painting with acrylic paint. Everything fits perfectly and stays on.Good luck everyone! nazir02.01.2012 14:01 what primer was used and how many times the thickness of the filler gaps how to cover up if it's not difficult please answer in advance please Sergey29.01.2012 04:09 After what primer? What was primed? Is it possible to putty without a primer at all? Sergey29.01.2012 04:25 For a better decorative effect, it is preferable to use sanded panels. However, manufacturers of OSB / OSB panels do not recommend application on or on OSB / OSB.

This is after someone who said that - Wallpaper can be glued, but there is no plaster. Tatiana24.07.2012 09:25 Brick garage (unheated). Is the wall cladding and OSB correct? How to expose the profile, and what gap should be between the plates? Ivan24.09.2012 13:00 Sheathed the OSB room, please tell me what else needs to be done for wallpapering??? Thanks in advance Valeriy24.01.2013 22:28 Weak overlap forced to lay the OSB along the lags along it, without a screed. Is it possible to glue floor tiles on OSB? What to pre-prime?

Finishing the walls of the house with OSB slabs - blogs - repair.ru

Finishing a country house is not an easy question, and for a long time I could not stop at choosing a specific finish, because on the one hand I wanted it to be beautiful, and on the other, it was natural that it would be inexpensive and fast. At first I just wanted to plaster and then paint the exterior and interior walls, but on one site I met a surprisingly effective and fairly inexpensive wall and floor finish. This finish is cheap and installs very quickly, so I decided to use just such a finish, this is called OSB board finish. The OSB boards themselves are made from wood shavings, and if such a board is sanded and even coated with varnishes and other compounds, then appearance this plate is simply uniquely beautiful. OSB boards are strong enough, as well as their moisture resistance and resistance to atmospheric phenomena are very high, so they are used not only for exterior decoration, but also for building a house. Today, whole small houses are being built from such plates and using beams, which are very strong and durable, that is, OSB is a very effective and durable material. I have a dacha made of ordinary shell rock, and I finished it with OSB slabs outside and inside, it’s easy to do, that is, first nail the bars to the walls and then attach the wood chip boards to the bars themselves. I did this decoration both inside the house and outside, it took me about four days no more to finish such a one-story house with an attic.

That is, the work of installing the plates is simple and if you have experience in such work, then you can do it faster, while the finish itself is really very high quality. boards are very high, this is due to the pressing of wood chips with their impregnation with a special glue emulsion of paraffin and adhesive waterproof resin. That is, thanks to this high-quality processing, such plates are not afraid of the rain of the sun's rays of snow, while preserving the unique properties of the wood itself. Such plates are much cheaper than even plywood, and the finish looks very cool, so if you don’t know how to decorate the house inside and out, then you can safely choose this material. You can fasten them with building brackets or just screws, such a plate is very wear-resistant and durable, and at the same time it is easy to process. OSB boards also have the property of shape stability, that is, they do not deform and have the ability to muffle sounds, that is, they have good sound insulation. The slabs themselves are usually made from pine chips, which are subjected to the barking itself, and then they are crushed, thus, the chips themselves are 10 cm long, usually 1-3 cm wide and of different thicknesses. After processing the plates, they have a very beautiful appearance and you can not even paint such polished OSB boards, that is, they look very aesthetically pleasing anyway.

Wall decoration - "osb plate", "minerite" and glass-magnesium sheet

High-quality wall decoration using modern materials - "osb plate", "minerite" and glass-magnesium sheet.One of the most time-consuming and costly processes in the repair of any room is the alignment of walls and ceilings. Not so long ago, only professionals with extensive experience in construction could perform these works with high quality. It was often very difficult to find such professionals, and their services were very expensive. Relatively recently, the so-called "dry" technology of wall finishing with the help of gypsum boards has appeared, which are mounted on a special metal frame, previously attached to the wall with self-tapping screws. The process of installing the plates is relatively simple and short, and even a non-professional can handle it.

At the same time, the subsequent surface treatment of gypsum boards is a rather lengthy and laborious process, it is necessary to go through a number of the following mandatory stages: sealing the joints, puttying, leveling the putty, priming the fasteners, fine leveling, and only after that it was possible to proceed to wallpapering or applying decorative coatings.

More recently, a number of new materials for interior decoration with more simplified installation have appeared. This is primarily: wall panels "osb plate", "minerite" and glass-magnesium sheets (LSU).

Wall panels "osb board" are decorative panels consisting of an oriented strand base and a high quality vinyl cover. When installing such panels, a special profile (“Omega-profile”) is attached to the metal frame, which is closed with a decorative strip. This profile provides reliable fastening of the OSB panels. Subsequently, such panels are easily removed and interchanged, for example, if it is necessary to move the hole for a socket or switch. It should be noted that the whole process of mounting OSB panels is extremely simple and does not take much time. In addition, after installation, you get a finished decorative surface that does not need further processing procedures, such as putty, etc. OSB board panels also differ from other types of coatings in their increased wear resistance, high strength and practicality, high fire resistance and environmental friendliness. Thanks to these qualities, it can be widely used both for home decoration and for decoration of various public premises (kindergartens, schools, restaurants, offices, etc.)

Minerite is another popular modern material used in wall decoration. Minerite is a rectangular sheet, which consists of a core (cement base with light mineral filler), which is reinforced on both sides with a fiberglass mesh. Minerite is a material with high water resistance, so it is often used for interior decoration of premises with a humidity of more than 85% (pools, saunas, baths, showers). This material is a good basis for any decorative coating. Minerite is also widely used for outdoor work, especially in frame construction. Due to its design, minerite can be easily bent (curvature radius up to 3 m), which makes it suitable for use in curved sections.

Another modern material is glass-magnesium sheets (GML). LSU is a sheet material based on magnesium chloride shavings and fiberglass. It is characterized by high strength, high moisture and fire resistance, good flexibility. In addition, this material is environmentally friendly. Magnesium glass sheet is widely used in wall and ceiling decoration, it is a good base for sauna, swimming pool, shower room, etc.

Osb-3: we use it wisely - osb-3 plates - mainland - building materials in st.

OSB-3: use it wisely

OSB is a particularly durable plywood, which is produced using a new technology. The material is not afraid of moisture. Therefore, it can be applied in various fields. Plywood does not give off moisture and does not absorb it, whether it is high humidity or rain. Therefore, moisture cannot affect the condition of the material, does not affect the service life of OSB boards. Plates are optimal for our climate, as they are not afraid of temperature changes. OSB-3 retains heat well, a house built from the material will not require large heating costs. The material is especially relevant in those regions that are characterized by warm summers and cold winters.

The most common way to use OSB-3 boards is to build walls. Plates can be used in frame housing construction. Due to the fact that OSB-3 does not warp, different wall finishes can be applied to clad walls.

OSB-3 is used as a continuous sheathing for roofing. The material can withstand high mechanical loads, which makes it indispensable for roofing. In modern construction, plywood is increasingly being replaced with OSB boards due to improved performance. Plates are also used for flooring. But such a floor will be more of a draft, the basis for further work on the floor. But in lightweight structures, OSB-3 can act as a single layer floor. It is allowed to use plates as a material, which is subsequently covered with linoleum, carpet, parquet.

In furniture production, plates have found application as structural elements. During concrete work OSB-3 can serve as a removable formwork. The material is used for the manufacture of trade and exhibition equipment, for the manufacture of reliable and durable containers for the transportation of goods.

Slabs are often used to create a base before laying finishing materials on various types of surfaces. Sanded OSB-3 boards allow you to create perfectly even support structures. If we use slabs in the construction of ceilings, we get the opportunity to create structures that optimally prevent deflection or deformation of wall and interfloor ceilings.

Installation of OSB-3

Anyone who has ever encountered plywood during construction work will be able to cope with the installation of OSB-3 boards. Laying of plates can be carried out using various fasteners: rivets, bolts, staples, nails, screws, glue. But when choosing fasteners, it is necessary to take into account the scope and features of the use of the structure. Nails are suitable if we arrange a ceiling or walls with the help of plates. We try to hammer the nail in such a way that the hat is hidden or slightly pressed into the surface. You can use acid-resistant nails that are not afraid of corrosion and rust, or wire nails. To install external facing panels, it is better to use acid-resistant fasteners.

When fixing the OSB-3 board, we use nails, the length of which should be 2.5-3 times greater than the thickness of the panels. If using OSB we decorate the walls and ceiling, then the fixation step is 10-20 cm along the edges of the plate and 20-30 cm in the middle. If we arrange the floor, then the fastening step can be increased by 10 cm. The indent of the fasteners from the edge of the OSB-3 plate should be 1.2-1.5 cm.

When mounting plates, you can also use screw fasteners. If OSB-3 is used in furniture production or in the manufacture of stands for exhibitions, then the obligatory condition for installation is the use of screw connections. In those structures for which a strong connection is especially important, screw elements are used.

When installing the plate in it, we prepare holes in advance. When drilling holes, pay attention to the diameter of the screw: the diameter of the hole must match the diameter of the fastener. The connection must be made in such a way that the cap does not fall into the front veneer. The use of washers is allowed, in some installations they are a prerequisite. Pay attention that the front part of the plate is not damaged or damaged during fastening.

Another way to fix OSB boards is to use adhesives. You can use any wood glue when installing OSB-3 boards. When choosing one or another type of adhesive, it is worth considering the load on the surface, the level of humidity during operation, as well as the required degree of connection. If gluing occurs during work, for example, finishing a room, then we choose a composition that will not have a harmful effect on the human body.

If during operation the structure will experience the adverse effects of the environment, then you can use phenol or epoxy composition. They guarantee high strength of connection of all elements. If you want to glue the OSB-3 board to a metal surface, then we opt for epoxy glue. On the surfaces to be glued, glue is applied in an even layer, before the composition hardens, it is necessary to remove excess glue. Surfaces must be pressed tightly against each other. To do this, you can use special screws or clips.

OSB-3 boards: fine finish

When choosing a material for finishing OSB-3 boards, you need to take into account the type of room and the features of its operation. The decorative effect that needs to be achieved will depend on this. Finishing materials can increase the durability of the surface, which is especially true when finishing some rooms. In most cases, the materials that are used for finishing wood can also be used for finishing OSB boards.

Before finishing the surface, carefully inspect the plates. If there are any defects and irregularities, then you need to use grinding. It will create a perfectly flat surface without knots and notches. Can be used over OSB-3 boards to give walls or ceilings a level surface. But at the stage of finishing and finishing, you should carefully follow the recommendations of manufacturers of finishing materials. Perhaps, under certain conditions, it is worth abandoning the formulations for water based, which can lead to swelling of the plate. Water-based formulations can cause strands to become pronounced.

If finishing is carried out in a residential area, for which the appearance of walls or ceilings is important, then you should opt for finishing materials that are made on the basis of organic solvents. If it is important for you how the surface will look after finishing, then even a water-based primer should be abandoned. We always use a primer, regardless of what type of finish we choose. Almost all manufacturers of OSB-3 boards recommend using a primer before starting finishing work as a preparatory step.

When finishing slabs from the outside of the building, it is necessary to use materials that are characterized by a high degree of wood micropores. To protect OSB-3 boards on the exterior walls of the house, we use transparent or opaque materials that are allowed for outdoor use. Those materials that have a low degree of penetration into the wood can be useful in the construction of short-term protection of OSB-3 boards. Glossy coloring compositions can be an alternative.

If we carry out the finishing of slabs indoors, then the above requirements for compositions on water

basis remain in effect. In the event that the appearance of the walls and ceiling has great importance, it is recommended to use sanded OSB-3 boards, which have a flat surface. For interior design, such plates are ideal. It is not recommended to use wallpaper and ceramic tiles for finishing such plates. If the plates are laid on the floor, then the best option for finishing them will be a varnish coating. You can cover the floor with flame retardant paints to protect the room from fire in case of fire. But remember that in most cases such formulations are made on a water basis. To prevent OSB-3 boards from swelling, choose a non-water-based flame retardant. It is not recommended to use flame retardant paints for finishing the outer walls of the building, decorated with OSB-3 boards. They are more suitable for interior decoration.

Go to section: Wood-based materials and moldings → OSB-3 boards

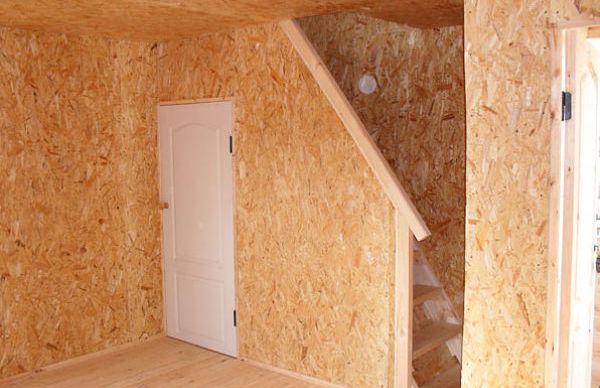

Before talking about the technical details and intricacies of the inner lining of OSB or OSB boards (they are also OSB, OSB sheets), it is worth considering the appropriateness of this event. Installation of OSB boards indoors takes place in two cases, namely:

- If you have a frame house and the frame has not yet been sheathed.

- If the pattern and texture of OSB boards are an element of decor.

If you just need to level the walls, then drywall is better suited for this purpose, as it is cheaper and more convenient to work with during installation and further finishing.

The technologies for the outer skin of the house are set out in the article:. Here we consider the issue of proper installation of OSB boards on the walls inside the house.

The choice of plates for mounting OSB on the walls inside the house

When using any material inside the house, including OSB boards, attention should be paid to its harmlessness to the health of the inhabitants of this house. Already 34 years have passed since the appearance of OSB boards and all these years the debate about the environmental friendliness of OSB boards has not stopped. In fact, there are grounds for these disputes, since indeed, when gluing wood chips, polymer resins containing formaldehyde are used. But formaldehyde is also found in many other surrounding things, for example, in fabrics in chipboard furniture, combustion products, etc.

OSB slabs on the walls inside the house.

In order to exclude formaldehyde poisoning of people, enlightened Europeans established control over the production of OSB boards and divided the harmfulness of boards into classes. Plates with formaldehyde emission class E1 are harmless to human health and are used in the construction of residential buildings. Therefore, when buying OSB panels, choose a reliable and trusted manufacturer, as your health may depend on it. The Austrian four-star hotel Arlmont, whose interior decoration is replete with OSB panels, will say better than any words about the environmental friendliness of OSB panels.

Arlmont Hotel, OSB sheets used in the interior.

Arlmont Hotel, OSB sheets used in the interior. OSB boards are divided into classes according to water resistance:

OSB-1 is the class of board most exposed to moisture and has the lowest strength. Such boards are used for the production of furniture.

OSB-2 is a class of boards with the same moisture resistance as OSB-1, but more durable. Such plates can be used for wall cladding in dry rooms.

OSB-3 - moisture resistant boards with high strength. They are suitable for installation in damp rooms. But with prolonged contact with water, they deform.

OSB-4 - boards with maximum moisture resistance. They are able to withstand prolonged contact with water.

OSB4 boards do not have wide popularity due to their price, which is on average twice as high as that of OSB3 boards. Therefore, OSB3 boards are widely used. If they are treated with a primer or painted with paint, then such plates become resistant to prolonged contact with water.

More details about various characteristics OSB sheets can be found in the article:.

Sheathing the walls of a frame house from the inside

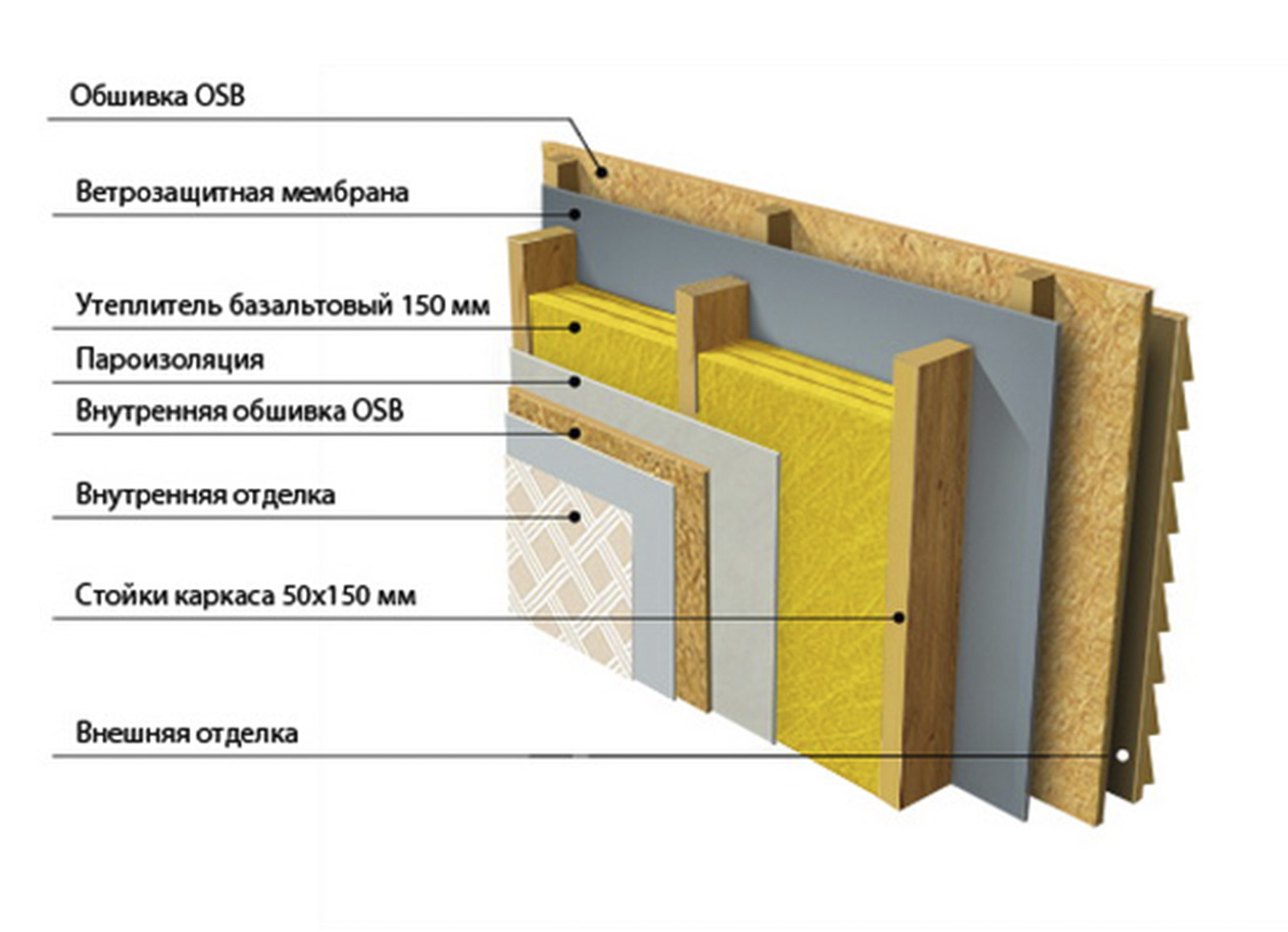

Before proceeding with interior trim frame house, it is necessary to insulate the walls, close the frame from the outside and the insulation with a vapor barrier.

It is recommended to insulate the walls with mineral wool, and it is better to use slab wool, since it is easier to work with than with expanded polystyrene, it holds better in vertical structures and does not settle down, which happens with fiberglass insulation. Other heaters are not excluded and are also suitable for insulating the walls of a frame house. For more information on various heaters, see the article:.

After the walls are insulated, they must be closed with a vapor barrier. The vapor barrier membrane protects the wall from the penetration of moisture into it, which will keep the frame of the house and the insulation dry. The vapor barrier is fastened with a conventional construction stapler, with an overlap of 10-15 cm and glued together with a special double-sided adhesive tape.

An example of the construction of the wall of a frame house. From the inside, a vapor barrier film is laid on the frame, OSB boards are attached on top of it.

An example of the construction of the wall of a frame house. From the inside, a vapor barrier film is laid on the frame, OSB boards are attached on top of it. The sheathing itself is made as follows, the sheets are alternately screwed to the frame of the house one after another. The gap between the sheets is 3 mm. Sheets are screwed with wood screws 35-40 mm long. All holes (for windows, doors, mounting holes) are cut with a jigsaw.

Decorative wall cladding with OSB boards and battens

As a crate, it is best to use a metal profile as for drywall. It is easy to install and does not warp like wood. When choosing wooden bars for battens, it is better to use dried wood bars, because such bars bend and twist less when they dry out. The installation technologies in both cases are not fundamentally different, so we will consider them using the example of a crate made of metal profiles.

In order to sheathe the interior walls with OSB boards, you need to start by installing the sheathing on the walls of the room.

The technology for mounting the crate looks like this:

1. First you need to install the starting profile, which is mounted on the adjacent walls, floor and ceiling as in Figure 1. On the sides, the profile must stand strictly vertically and close along the perimeter with the upper and lower profile.

Figure 1. The start profile is mounted to the adjacent wall. And closes with the top and bottom profile.

Figure 1. The start profile is mounted to the adjacent wall. And closes with the top and bottom profile. 2. After installing the starting profile, it is necessary to make markings on the wall for suspensions. Since the hangers will hold the vertical posts of the crate, you need to mark it in such a way that two solid OSB sheets meet in the middle of the profile, you also need to install one profile in the center of each solid OSB sheet.

Hangers are attached to the wall. A crate is attached to them.

Hangers are attached to the wall. A crate is attached to them. 3. We mount the profile. When fixing the profile on hangers, it is important to control the plane of the lathing with the rule so that “pits” or “belly” do not form on the wall in the future.

Installation of OSB boards on an internal wall using a crate.

Installation of OSB boards on an internal wall using a crate. After mounting the crate, we fasten the panels to the OSB screws with a gap of 3 millimeters between them. The gaps allow in the future to avoid deformation of the plates due to their expansion with changes in humidity. After installation, the finished walls can be varnished or tinted, based on individual preferences.

Oriented strand board is a fairly popular building material that is most often used to level the surface of walls and build interior partitions.

However, there is an opinion that these multifunctional units do not always meet the established environmental requirements.

The harmfulness of OSB for interior decoration is due to the presence of various resins used in the production process.

But do they really pose a risk to human health?

OSB production technology

Experts also advise not to lose sight of the ends, which are enough to cover with edge tape. It seals the surface of the plates well, minimizing toxic fumes, ordinary puttying and pasting the walls with thick wallpaper.

The degree of harmfulness of the OSB board can be significantly reduced if, during interior decoration, this material is used exclusively for rough work.

However, if even if all operating standards are observed, the purchase of plates causes some concern, then it is better to look for blocks made using only natural resins. They are much more expensive, but they are considered environmentally friendly material.

The category of similar products also includes cement-bonded particle boards, where mineral mixtures are used as a binder.

Simple Rules

When installing plates, it is almost impossible to avoid the accumulation of formaldehyde and similar substances in the air. But this problem is easily solved with the help of careful ventilation of the room.

Daily airing and damp cleaning will also help mitigate the potential harm from fumes. For reliability, you can also install a supply and exhaust system.

The rate of elimination of toxins is affected by high air temperature, so the thermal regime in the room where there is OSB should not exceed 30 degrees. An increase in this indicator for every 5 points automatically doubles the amount of harmful fumes in the air.

Formaldehyde is highly soluble in water, so when the humidity level rises to 70 percent, potentially hazardous substances are released 40 percent more intensively.

Video about the options for using plates as cladding:

You can also clean the air from accumulated fumes with the help of indoor flowers. According to experts, dieffenbachia, familiar to many housewives, perfectly copes with this work.

OSB (Oriented Strand Board) is a popular material that is used for a variety of applications. Most often it is used for wall cladding and creating various partitions. Therefore, more and more often there is talk that the harmfulness of OSB boards for interior decoration is quite high, and it should be completely excluded from construction work. But is it really so?

To understand what can pose a threat to humans, it is necessary to study the OSB production technology. It is divided into several stages:

- Receipt and processing of raw materials. In this capacity, waste from wood processing and its non-business part (rejected) act. It is carefully soaked at a certain temperature and cleaned of bark. This is an important step - otherwise you will get a low-quality plate.

- Chip cutting. This process is carried out by special machines.

- Drying of the obtained raw materials. This process takes some time. Rapid drying can damage the wood chips.

- Mixing with adhesives. The procedure takes place in a drum, into which the required amount of chips, resin and additional components are fed.

- Next, the molding machines stack the material in layers. There must be at least three of them. Each of them is oriented in a given direction. Adjacent layers are perpendicular.

- Press (hot) crushes the resulting mass. Cropped to the desired size.

For the production of OSB boards, special press machines are used.

For the production of OSB boards, special press machines are used. Thus, the basis is environmentally friendly raw materials - wood. But the danger may lie in the adhesive composition, or rather in formaldehyde resins.

On a note! Even natural wood can emit formaldehyde (within the current allowable norm). Therefore, talking about the complete safety of freshly cut trees is a rather controversial decision. Each material needs processing or curing.

Formaldehyde and other hazardous substances

In fact, it is quite possible to make OSB boards from natural resins that are diluted with minor additives. But this technology is quite expensive, and also does not allow the production of the required volumes of material. Therefore, the adhesive mass is replaced with a mixture of formaldehyde, phenol and other toxic substances.

Their presence in the air leads to the following problems:

- The appearance of allergic reactions and frequent headaches.

- The occurrence of skin diseases.

- Difficulty breathing and constant tearing of the eyes.

- General decrease in immunity.

High levels of formaldehyde and other hazardous substances in the air can lead to negative health effects

High levels of formaldehyde and other hazardous substances in the air can lead to negative health effects A certain threshold of formaldehyde content has been established. It is - no more than 0.5 mg per m3.

On a note! Do not confuse the norms of the content of a substance in the air and the material. These figures vary.

OSB boards - harmful or not?

Production of OSB boards began about thirty years ago in Canada. Then production began to appear throughout North America and European countries. For the countries of the post-Soviet space, this is a relatively new technology, which is mostly borrowed from abroad. But there are enterprises that work on cheaper equipment, excluding some stages from the manufacturing process (replacing them with cheaper ones).

OSB boards - real harm or myth?

OSB boards - real harm or myth? Currently, OSB boards are labeled based on European standards. Namely, they use a formaldehyde resin emission classifier. The designations are:

- E 0.5. Permissible rate is up to 4 mg per 100 g of dry slab. In this case, the content in the air will be up to 0.08 mg per m3.

- E 1. Limiting norm - up to 8 mg. In the air, the concentration will be up to 0.124 mg per m3.

- E 2. The content per 100 g of dry matter is up to 20 mg, while the content in the air is 0.5 mg.

The data are based on GOST 10632-2014. Of course, Western standards are much tougher.

Thus, it becomes extremely clear that any contains formaldehyde in its composition. But because of what many claim that the concentration of harmful substances literally rolls over?

OSB boards of foreign production are subject to more stringent quality control

OSB boards of foreign production are subject to more stringent quality control There are several reasons:

- Firstly, all foreign manufacturers comply with environmental standards. But at present, a lot of materials have appeared on the market of the CIS countries, which were produced on the territory of some Asian states. It is they that contain chemicals in their composition, the norm of which significantly exceeds all permissible standards. The popularity of such plates lies in their low cost.

- Secondly, some small producers located in the territory of the post-Soviet space violate the production technology. For example, modern manufacturers have achieved a reduction in the amount of harmful substances by separating production. Namely:

- The outer and inner oriented strand layers are mixed in different chambers: the first - with the addition of natural resins with a minimum amount of chemicals, the second - with the addition of formaldehyde and additional components.

- This allows you to "seal" harmful fumes inside the sheet. But this method increases the costs of the enterprise.

The low price of OSB boards may indicate not only the poor quality of the material, but also the high content of harmful substances

The low price of OSB boards may indicate not only the poor quality of the material, but also the high content of harmful substances That is why, when purchasing an OSB, you need to pay attention to the following:

- Smell. Toxic substances give a sharp, unpleasant odor, which immediately "clogs" the sinuses.

- Certificate. Every seller should have this document. Even if this procedure is voluntary for some materials, then a self-respecting manufacturer passes it without fail.

- Marking. The manufacturer must mark each sheet. The end contains all the necessary indicators and characteristics.

- Price. When a product is suspiciously cheap and sold in illegal markets, neither quality nor safety can be guaranteed.

But there are general rules, which can significantly reduce or completely reduce the release of harmful substances.

Marking OSB boards - detailed information about the material

Marking OSB boards - detailed information about the material Some rules for more safety

The first time (about six to seven months) after installation, the most intensive emission of harmful fumes occurs. If you regularly ventilate the room, then soon the negative impact on the body will begin to subside. But for greater safety, additional processing of the plates is carried out.

If the work takes place in the children's room, then compositions with detoxifying properties are chosen as a primer. For common areas simple water-dispersed paints, varnishes, wax, penetrating primer are suitable.

Particular attention is paid to the ends. It is through them that the main amount of harmful substances is released. It is enough to impregnate them with varnish or primer.

Priming is one of the safety measures to reduce the amount of harmful substances emitted

Priming is one of the safety measures to reduce the amount of harmful substances emitted On a note! A simple surface coating is the best guarantee of protection against the emission of harmful substances.

It should be borne in mind that the rate of release of toxic elements is affected by temperature. The higher the indicator, the more formaldehyde in the air. The norm is - 30 ° C.

In general, there are two main ways that allow, without making excessive efforts, rid the room of chemical components and saturate it with oxygen. Namely - frequent airing and the presence of indoor flowers.

OSB is not recommended for use in rooms where the temperature exceeds 30 °C.

OSB is not recommended for use in rooms where the temperature exceeds 30 °C. Any modern building or finishing material that is made using chemical components can emit harmful substances. But manufacturers are constantly trying to keep these figures to a minimum.