Wood is considered to be the first building material that people began to actively use in their life. In addition to natural origin, it has a solid set of advantages. This ensures the high popularity and demand for wooden products and structures. At the same time, this material still has one, but a significant drawback: it needs protection from moisture. For this purpose, not only wood sealants are used, but also acrylic-based oils and varnishes. They differ in characteristics, composition and properties.

What is acrylic lacquer

In general, acrylic paints and varnishes are made on the basis of acrylic polymers. They were first obtained in 1952 by specialists from the well-known American company DuPont. The polymers were easily dyed, did not react to the action of water, acids, alkalis and ultraviolet radiation. These materials laid the foundation for the creation of a line of acrylic varnishes. In addition to polymers, they include water and plasticizers. The latter are necessary to increase the elasticity of the varnish after drying. Such mixtures are one-component. Two-component varnishes additionally contain hardeners that increase the strength of the coating.

Types of acrylic varnishes

By appearance final coating acrylic varnishes can be matte, glossy and semi-gloss. In addition, they differ in purpose. On this basis, compositions for the floor, for external and internal work are distinguished. After drying, floor varnishes create an elastic, but durable film. It maintains integrity during the deformation of parquet or boards, which is the result of a change in temperature. A feature of the compositions for outdoor work is resistance to ultraviolet radiation, water, high and low temperatures. Varnishes for interior work have similar properties, with the exception of frost resistance.

Characteristics of acrylic varnishes

Externally, acrylic varnishes are a viscous, odorless liquid. The final protective coating is formed as a result of the evaporation of water from it. The resulting elastic film protects the surface from mechanical damage and ultraviolet radiation. In a liquid state, up to 10% of water can be added to acrylic varnishes, but after drying, they cease to be water-soluble. They can be applied with rollers or brushes. Additionally, it should be noted that such mixtures are characterized by high adhesion to the surface.

The use of acrylic varnishes

Acrylic varnishes have several uses:

Finishing of wooden floor coverings;

External and internal woodwork;

Processing of interior elements of premises (chairs, railings, decorative figurines, flights of stairs, bedside tables, etc.);

Decoupage works;

Reconstruction or renovation of old wooden buildings.

How varnish works

After being applied to a tree, during hardening, the varnishes form a strong and elastic film, without penetrating deep into the pores. Such compounds level the surface without being absorbed into it, while they change the texture of the surface, making it resistant to abrasion.

Advantages and disadvantages of acrylic varnishes

Acrylic varnishes have a number of undeniable advantages. The main one is the absence of harmful odor and toxic emissions. In addition to environmental friendliness, the following advantages of the compositions can be distinguished:

- good antiseptic properties: acrylic varnishes protect wooden surfaces from mold or fungus;

- fire safety provided by the water base;

- resistance to mechanical stress and ultraviolet radiation;

- high decorative effect.

When using acrylic varnishes, their disadvantages must also be taken into account. So, they are able to form a strong and elastic film on the surface of the tree, but at the same time completely deprive it of the ability to absorb and release moisture. For this reason, the ability of the material to maintain an optimal microclimate in the premises is deteriorating. In addition, with changes in temperature and humidity, the tree begins to change its volume up or down. Despite the elastic properties of the lacquer film, deformation and peeling of its top layer become noticeable after a while, so restoration is required. In addition, damaged areas lose their protective properties and, as a result, mold or fungus can form in them.

Oils for wood processing and their types

Another effective and common way to protect wood is oil treatment. They can be used for outdoor and indoor work. For this purpose, various natural-based formulations are used. They are divided into three categories: non-drying, semi-drying and drying.

Non-drying are represented by almond, palm, olive and castor oils; semi-drying - cotton, rapeseed and sunflower; drying - hemp, linen, perilla, walnut and poppy. To increase wear resistance, special chemical components can be added to oils.

The most popular are flax and hemp compositions. The former contain a large amount of polyunsaturated fatty acids, harden faster and penetrate the wood best. Hemp oils are similar to flaxseed oils, but, in addition, they contain substances that perform antiseptic functions.

Oil compositions can be used to treat any wooden surface. In this case, the moisture content of the material should not exceed 14%. External work should be carried out on a sunny day, and internal work should be carried out at a humidity of no more than 70%.

Characteristics of oils

Oils are thick liquids with a mild natural odor. After application, they harden under the influence of oxygen and sunlight, forming a protective coating. Such compositions successfully mask mechanical damage on the surface of the tree. The final coating allows you to keep its original structure, making it pleasant to the touch. The oils impart an attractive matt sheen to wood products and provide protection against moisture, fading, decay and fungal attack. Such compounds need to be rubbed in, so they are applied with a special stiff brush, and the excess is removed with a rag.

Application of oils

Oils have a similar scope to varnishes. All used compositions can be divided into three large groups, differing in composition and properties:

- Means for the protection of facades are characterized by resistance to temperature extremes and external atmospheric influences;

- Oils for walls, ceilings and interior items contain wax in small proportions to increase strength characteristics;

- Compounds for the floor are highly resistant to abrasion. For this purpose, natural waxes are added to them. They increase the life of the coating and give it dirt-repellent properties.

Additionally, it should be noted that all types of oils are resistant to ultraviolet radiation.

For processing precious woods, it is better to use wax based on flax composition.

How oil works

Unlike varnishes, oils penetrate deep into the structure of the tree after application. At the same time, they do not change the texture of the surface, but emphasize it. The surface remains embossed, acquiring a slight matte sheen. Oils after hardening do not form a protective film and have high vapor permeability. They tightly envelop the tree, increasing its strength characteristics, durability and wear resistance.

The oil hardens the longest on products made from abacha (an exotic wood species). Products from it can be used only two weeks after applying the composition.

Advantages and disadvantages of oils

Natural oils contain only environmentally friendly components. They can be safely used in premises of any purpose. In addition, such compositions have the following advantages:

- are well cleaned of contaminants;

- do not change the natural color of the tree;

- do not exfoliate, do not deform and do not peel off during operation;

- have high wear-resistant and water-repellent properties;

- reliably close even the smallest pores of wood;

- create a non-slip, impact-resistant shell;

- allow air to pass through, which ensures ventilation and maintenance of the natural microclimate in the premises.

At the same time, some disadvantages of natural oils should be noted. So, they are somewhat more expensive than acrylic varnishes. In addition, after hardening, the oils contribute to the accumulation of dust, so the surfaces treated with them need regular maintenance.

findings

Oil protects wooden structures more reliably, but still, any coating will require updating sooner or later. The influence of the sun, weather conditions or mechanical influences inevitably makes itself felt. As a result, for example, characteristic abrasions appear on the floor, which differ in shade in places of greatest stress. The facade noticeably fades, some sections of the wall become lighter than others. A similar picture indoors. Thus, sections of the walls protected by paintings look fresher and brighter than those nearby. In such cases, the difference between the two means is best manifested.

In the presence of an oil coating, it is enough to process only the damaged section of the wall, product or floor. The difference in shades will be imperceptible. It won't work with lacquer. You will have to change it entirely, because the difference between the old and new layers will clearly stand out. In addition, the average varnish consumption is 150-250 g/m 2 , and the same indicator for oil is 50-70 g/m 2 . Given the characteristics of the restoration, it is it that is the more profitable option. Also, one should not forget that oil, as opposed to acrylic compositions, preserves the natural beauty and texture of wood.

Among the large assortment of paints and varnishes, a special niche is occupied by film-forming mixtures, namely varnishes. With the development of innovative technologies, manufacturers of these compositions are inventing more and more varieties of varnishes. They differ not only in physicochemical properties, solvents, but also in surface quality. Among the extensive range of varnish compositions, acrylic mixtures occupy a special place.

They are an environmentally friendly material due to the absence of organic solvents in them. You can choose any composition from a well-known manufacturer, for example, Nerchau, Olki, Tair, Sonnet, Decola, Tl or Kudo 336 acrylic glossy varnish, but first you should study the features, advantages, disadvantages and scope of such mixtures.

Lacquer Features

Acrylic varnish compositions are a mixture based on a dispersion of plastics, which can be completely dissolved in water. During the development of this composition, the special properties of resins were used. This material, after drying, can form a dense, impermeable protective film, since a combination of acrylic material and a plastic dispersion is used in its structure. This varnish can be matte or glossy.

Acrylic mixture allows you to get a durable coating that can protect the surface from aggressive factors external environment and mechanical damage. Such properties of the varnish composition were appreciated in the countries of Western Europe. Here, its production was put on stream, since the varnish began to be used not only in the construction industry, but also in various areas of the chemical industry. So, colorless varnish became the basis for the manufacture of paints and varnishes, which are used for impregnation and treatment of various surfaces, raw materials for the manufacture of various adhesives and building mixtures.

It doesn’t matter which varnish you decide to use, matte or glossy, they have the same composition:

- acrylic dispersion is a liquid polymer component;

- antiseptic, which performs protective functions in relation to wood products;

- plasticizer, allowing you to get a transparent varnish layer.

Varnishes of any brands (Tair, Sonnet, Decola, etc.) are a transparent, colorless composition of a homogeneous consistency. This material is soluble not only in an aqueous medium, but also in ethanol, diethyl solution and ethers.

Such varnish compositions have the following physico-chemical properties:

- It is a viscous, water-soluble substance.

- For a varnish based on acrylic resins, an almost complete absence of smell is characteristic.

- Both matte and glossy acrylic varnishes tend to form an elastic protective film on the surface that is resistant to mechanical damage.

- The composition dries in the process of evaporation of water.

- After drying, the film cannot dissolve under the influence of water.

- The substance does not turn yellow from sunlight.

- The mixture gives good adhesion to any surfaces.

- This is a quick drying lacquer.

- The varnish is completely ready for use (it does not need to be mixed with other components).

- If necessary, acrylic mixtures can be mixed with other water-soluble paint compositions.

Universal acrylic varnish brand Sonnet, Tair, etc., if necessary, you can:

- dilute with water (at the same time, its content should not exceed 10 percent of the total volume of the mixture);

- make a brick surface treatment;

- use any standard tools for applying paints and varnishes - rollers, brushes, spatulas;

- apply in liquid and paste form (in any case, after drying, you will get an even, smooth, shiny surface).

Attention: acrylic lacquer can only be thinned with water, as it belongs to water-soluble lacquer mixtures.

Advantages of acrylic varnish mixtures

Varnishes based on acrylic resins from any manufacturer (Tair, Sonnet, etc.) have a number of undeniable advantages:

- Panel acrylic varnish, for example 336, is resistant to any temperature changes.

- The coating has increased moisture resistance and thermal conductivity.

- The resulting film is resistant to ultraviolet rays.

- The material has a low specific gravity.

- The material is completely harmless to humans and animals, as it is made from environmentally friendly ingredients.

- Thanks to the antiseptic components in the composition of the varnish, the film reliably protects against mold and other microorganisms.

- Colorless varnish material has high aesthetic qualities.

- Processing with such a varnish can be done even in places with an increased fire hazard, since the material does not support combustion.

Varieties

Lacquer of any manufacturer ( Olki, Tair, Sonnet, Decola, etc..) according to their composition can be divided into two groups:

- one-component (acrylic is used in the composition);

- two-component varnish based on acrylic and polyurethane.

Depending on the type of coating, these mixtures can be divided into the following subspecies:

- If you want to get a pleasant silky surface with a slight velvety, then use a matte acrylic varnish.

- A glossy shiny surface can be made using an acrylic-based glossy composition.

- For a medium-weight finish, a semi-gloss panel varnish can be used.

Important: Acrylic lacquer materials are excellent wood finishes. The mixture penetrates well into the pores of the material, emphasizes its beauty and allows you to get a durable moisture-resistant protective coating.

Scope of use

Acrylic panel lacquer is used in various industries. There are several areas of application of such material:

- This varnish can be made beautiful decorative finish of wooden surfaces. It is often used to protect furniture wood products from pests, moisture, wear and tear. At the same time, the mixture emphasizes the beauty of wood and prolongs the service life of products made from this material.

- Very often in construction, a diluted acrylic composition is used to coat various surfaces. The composition dries quickly, protects finishing and building materials from moisture. The most important advantage of such compositions is that they do not change the original color of the surface .

- Quite often, wooden decor in the interior is protected with acrylic lacquer solution. Such processing can be done not only for decorative elements, but also for wooden furniture (stools, bedside tables, cabinets, chairs, countertops, etc.). Acrylic varnish is used to paint stair railings, spans and wood paneling.

Quite often, Tair acrylic-based varnish is used during repair work, because it allows you to increase the moisture resistance of the treated surface.

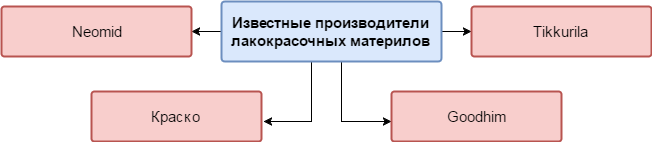

Manufacturers

The lacquer of domestic production of the Tair company enjoys considerable popularity. It is a water-based solution based on colorless acrylic resin without the addition of pigments. To improve performance, stabilizing and thickening components are added to the mixture. This varnish can be mixed with gouache, acrylic, tempera water-soluble paints. At the same time, after mixing, their properties remain unchanged, however, the saturation of the tone and the brightness of the color are enhanced. After mixing, the drying time of the composition is slightly increased.

Tair acrylic mixtures are used to strengthen and prime surfaces, to level or reduce the absorbency of the base. Also, the composition increases the moisture resistance of the surface, gives the necessary rigidity to textile substrates, and is suitable for repainting colored products. Tair Gloss Lacquer overlays matte paints for a moisture resistant, shiny and smooth finish. The price of the composition is $ 1.6 for a 100 ml container.

The ZHK plant produces Sonnet acrylic gloss varnish based on acrylic dispersion. This mixture is used for finished paintings that are painted with acrylic or tempera paints. The composition is also suitable for finishing wooden surfaces. After application, a durable glossy film is formed, which does not dissolve with water. The first setting of Sonnet varnish occurs 4 hours after application. The final coating hardens in a day. For a jar of 100 ml, you will have to pay about $ 3.

What properties does acrylic lacquer have, and for what purposes is it used? I've thought about this before. Now, having gained experience in this matter, I will accurately convey the technical points, as well as give a few mini-reviews on varnishes from well-known manufacturers.

What is the material

General information

Acrylic varnish is an aqueous dispersion of acrylic polymers. In other words, it is varnish on water based.

The main feature of the acrylic polymer is its crystal transparency. Thus, acrylic varnishes are one-component, ready-to-use coatings in the form of a colorless and completely transparent liquid.

Their main advantage lies in high physical and chemical properties. The varnish is able to reliably protect surfaces from mechanical influences and aggressive chemical environments.

The composition of this material usually includes the following components:

- Acrylic dispersion;

- plasticizer- provides the formation of a transparent film on the surface after applying the composition;

- Water- serves as a dispersed medium, which evaporates after application;

- Various additives- provide the material with certain properties, for example, water-based acrylic varnish for wood usually contains antiseptics that protect wood from decay and other biological influences.

Acrylic paints and varnishes appeared on the domestic market in the 90s. They very quickly gained immense popularity and today are in the greatest demand.

Acrylic varnishes are used not only for wooden surfaces, but also for many other materials, such as:

- Plywood and various wood-shaving materials;

- Vinyl;

- Paper;

- Brick;

- Natural and artificial stone;

- Glass fiber;

- Concrete, etc.

Key qualities

Like any other paint and varnish material, the coating in question has both positive and negative qualities. Therefore, we will consider all its properties further.

Advantages:

- Environmental friendliness. The material is almost completely odorless, since its composition is water dispersion, i.e. without organic solvents;

- fast curing. Hardening occurs by evaporation of water, respectively, the coating dries a few hours after application;

- Elasticity. Due to this, the coating does not crack;

- Moisture resistant. After hardening, the formed film does not dissolve in water and even withstands washing;

- Has good adhesion. Thanks to this, this paintwork material can be applied to the most different surfaces, while the film formed by it does not exfoliate. In particular, varnish can be applied over paint or tint as a top coat;

- UV resistant. The coating does not turn yellow even under direct sunlight;

- Durability. The service life is more than 10 years;

- Abrasion resistance. Thanks to this, the coating can even be used for floors;

- Ability to work with conventional tools. The coating is easy to apply with your own hands with a brush or paint roller;

- Weather resistance. Not afraid of high temperatures, no frost, no precipitation. Thanks to this, the material can be used not only for internal, but also for external work.

Water-based acrylic lacquer can be thinned with water if, for example, its quantity is insufficient. The only thing, in this case, the amount of water should not exceed 10 percent of the amount of the varnish itself.

disadvantages:

- Raises the fibers of the wood. Since the varnish is water-based, the wood fibers swell and rise during application. As a result, the surface is rough and unattractive.

True, the instructions for eliminating this effect are quite simple - the wooden surface must be slightly moistened before applying the coating, and then sanded. You can do otherwise - immediately apply varnish, and sand the first layer after it hardens;

- Low dry residue. As a rule, this figure does not exceed ten percent;

- Relatively high cost. This disadvantage applies to all polymeric varnishes and paints.

Varieties

Acrylic varnishes are classified according to the type of surface they form. Depending on this, they are divided into three types:

- Glossy. Form a film on the surface that can reflect light and even objects;

- Matte. The film formed by this coating practically does not shine and does not reflect objects.

It must be said that the matte acrylic lacquer has an attractive silky texture that gives the surface a somewhat silky feel; - Semi-matte. They are an average option between a matte and glossy finish. Like glossy varnish, semi-gloss compositions have some shine, but at the same time, objects are not reflected on their surface.

If you want to achieve the effect of deep "glass", you should apply varnish on varnish in several layers.

Brief reviews of some varnishes

Finally, I will give short reviews varnishes from some well-known manufacturers on the domestic market:

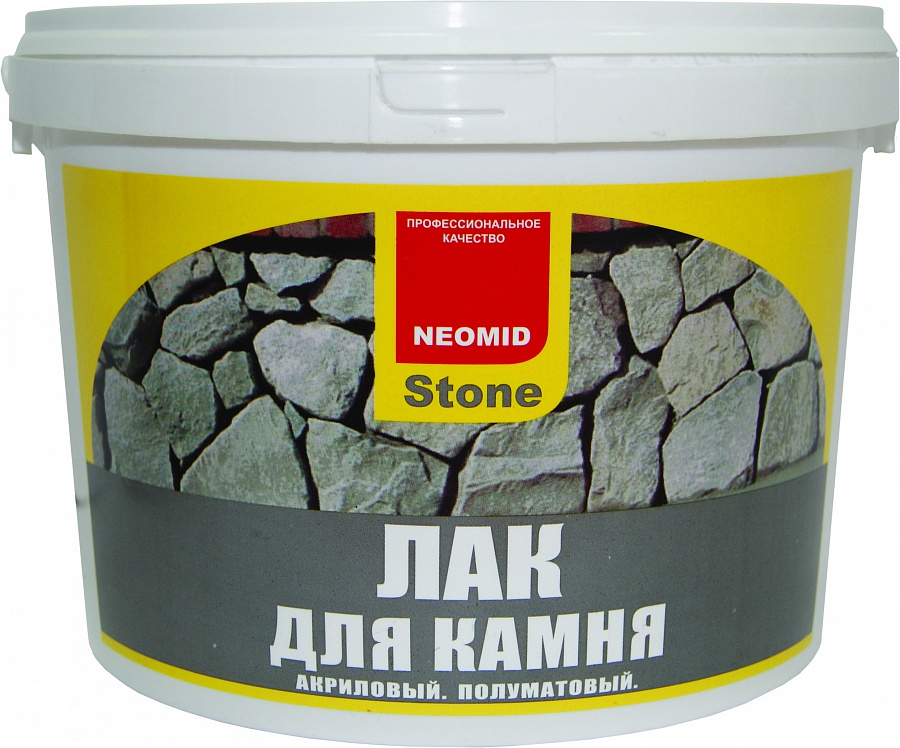

neomid

Neomid is a domestic company that has been manufacturing paints and varnishes since the mid-2000s. Due to the high quality of its products, it supplies paints and varnishes not only to all regions of Russia, but also to neighboring countries.

Neomid introduced several acrylic lacquer options to the market. The following deserve special attention:

- Neomid Sauna. As you might guess, this coating is intended for baths and saunas. The main advantage of the material lies in its environmental friendliness.

In addition, the material is resistant to constant exposure to high temperature and moisture. At the same time, it reliably protects wood from fungi, mold, etc. The film also has a dirt-repellent property;

- NEOMID Stone. This coating is designed to be applied to stone or mineral surfaces - brick, concrete, etc. The coating creates the effect of a "wet" stone on the surface. In addition, a layer of varnish prevents the occurrence of efflorescence, mold, and also protects against precipitation and other negative influences.

Price(updated in spring 2017):

Krasko

Drevolak from the domestic manufacturer Krasko is a universal acrylic protective and decorative coating for wood, which can be used for the following purposes:

- To cover facades wooden houses;

- For decoration internal walls houses;

- For garden and home furniture;

- For fences, barriers, etc..

The peculiarity of this material is vapor permeability. Therefore, after processing the wooden walls in the house, the natural microclimate is not disturbed.

In addition, it is resistant to any atmospheric influences, so it can be used even in harsh climates.

The price of Krasko Drevolak starts from 250 rubles. for 1 kg.

goodhim

Goodhim is another well-known paint manufacturer today that has introduced Goodhim TEXTURE, a versatile water-based acrylic clear coat, to the market. It can be used for decorative finishing not only wooden, but also mineral surfaces. Moreover, it can be used for both outdoor and indoor work.

I must say that Goodhim TEXTURE is not only transparent, but also tinted. The line has 10 colors, including such popular colors as walnut, rosewood, oak, metallic, etc.

The cost of this coverage is 200 rubles. per litre.

Tikkurila

Above, we considered coatings for almost all surfaces, with the exception of floors. Therefore, in the end I will tell you about the parquet varnish from the famous Finnish Tikkurila - PARKETTI-ASSA.

This paintwork material is characterized by all the qualities that I talked about above. In addition, it has high wear resistance. Thanks to this, it can be used for floors even in rooms with high traffic.

Another advantage of PARKETTI-ASSA is that the surface can be washed using any detergent and even wiped with white spirit. Despite these properties, the material remains environmentally friendly, which can be used in residential areas.

Bank Tikkurila PARKETTI-ASSA, with a capacity of 9 liters costs 8600 rubles.

Conclusion

Now you know what a colorless acrylic varnish is, what properties it has, and for what purposes it can be used. Watch the video in this article for more. If any points have raised questions in you, ask them in the comments, and I will definitely answer you.

A water-based acrylic wood varnish applied by a skillful hand not only gives the surface an aesthetic appearance, but also protects it from many adverse factors. Acting as a kind of “armor”, a water-based varnish for wood protects surfaces from moisture and atmospheric phenomena. It effectively protects the tree from pests and premature natural aging. Where can this finishing material be used, how to choose it correctly and how to work with it?

The technology for the production of acrylic paints and varnishes (LKM) is relatively young - it has been counting its history since 1952. Due to their properties, such compositions rapidly gained high popularity and wide distribution throughout the world. Today, this material for painting and protecting surfaces and objects made from various types of wood is used in a variety of fields and areas.

The composition of a water-based acrylic lacquer includes, as a rule, the following components and components:

- acrylic dispersion. A material based on a complex technology for processing essential elements of polymer resins - acrylic, cyanoacrylic or methacrylic acid;

- plasticizer. A substance that gives the varnish or paint optimal plasticity, the necessary consistency and proper binding properties;

- Antiseptic additives and impregnations. It is they that give the dispersion high protective properties, providing additional surface protection from mechanical influences, environmental influences and the creation of an additional laminating film.

All these components in various proportions are mixed on a water basis with a uniform degree of intensity. Since the acrylic varnish for wood at the output is a transparent and absolutely colorless liquid of a homogeneous consistency, a certain stage of production involves the addition of various coloring agents to its composition. This is done not only to ensure that the colorless dispersion has, for example, a white color or a glossy texture. Modern powder paint is able to form additional protection against adverse effects of various kinds.

In addition, today, in addition to resins, various components based on polyurethane are often added to the composition of water-based acrylic varnish for wood. Such coatings are called "two-component", and their ability to form a protective film and a decorative component significantly exceeds the capabilities and consumer properties of one-component water-based wood varnishes.

Main advantages

Gone are the days when compositions for coating wood products and surfaces left much to be desired in terms of their environmental performance and impact on human health. Unlike oil-based or purely chemical-based coatings, modern acrylic varnish or paint has a number of quite obvious and undeniable advantages. The main ones are the following:

- environmental friendliness, safety for health, no harmful emissions;

- high fire resistance and fire safety;

- immunity to moisture and to the effects of atmospheric phenomena, or temperature extremes;

- resistance to direct sunlight and ultraviolet;

- resistance to active chemical components and aggressive environments;

- good antiseptic properties that prevent the accumulation of dirt, the formation of mold or fungus;

- effective protection of wood from decay and pests;

- easy application, quick drying, unpretentiousness in personal care;

- durability and resistance to mechanical or impact loads;

- aesthetic appearance, a variety of textures, textures and colors.

Due to such high consumer and functional properties, the composition has a high versatility of application. With its help, you can solve a wide variety of tasks, perform both external and internal finishing work, applying it in various fields and areas. Such compositions are often used not only in the field of repair and construction, but also in art, for example.

Application specifics

Speaking about the areas of application of acrylic varnishes for wood, it is necessary to mention one more type of classification of this commodity group of coatings. The fact is that, according to the appearance of the final result, such compositions can be conditionally divided into three large groups:

- Glossy. The most popular type in the production of decorative work on the processing of parquet and other types of wooden floor coverings. Enhances the shine of polished wood. Often used to create a "mirror" floor effect. Often found in palaces, mansions, museums or luxury homes. Sometimes it is used to decorate objects and products made from various types of wood. Requires serious care and respect;

- Matte. A much more common type, the composition of which is arranged in such a way that the surface can acquire a wide variety of colors. In addition, matt acrylic lacquer successfully masks irregularities and defects in the coating, has higher wear resistance and unpretentiousness in personal care. It is much more durable than a glossy finish and gives the wooden surface a certain silkiness or velvety;

- Semi-matte. It occupies an intermediate position between the two types listed above, combining the advantages of both. Finds the widest application in construction, when carrying out repair and finishing works, both internal and external.

Regardless of which of the above groups it belongs to, the finishing composition, in addition to its decorative abilities, has another important and useful property. It is able to penetrate deep into the pores of a wooden surface, giving it increased moisture resistance and significantly increasing its durability. That is why professionals prefer acrylic paintwork materials when compared with conventional, traditional paintwork materials.

Note! Since acrylic varnishes for wood are water-based, they should only be diluted with water! The use of drying oil, solvent and other paints and varnishes is unacceptable!

Applications

Due to their properties and the advantages that acrylic coatings have, which were discussed above, they have found application in a wide variety of fields and areas:

- construction and repair, protection of wooden structures;

- decoration of wooden surfaces and products;

- creation of interior design elements;

- internal and external finishing works.

Such paints and varnishes are actively used in suburban construction, when processing furniture or furnishings made of wood, for decorating facades or wall panels. The areas of application of finishing and decorative compositions based on acrylic resins are very wide and varied. Due to the ease of application, quick drying, high aesthetic properties, such compositions look much more preferable than oil paint. No wonder today these paintwork materials are successfully replacing it in the production of finishing or repair work. Moreover, they can handle not only wood surfaces and products.

Matte and glossy acrylic lacquer:

The unique characteristics of water-based acrylic coatings determine their wide distribution and high popularity. They give the surfaces a unique aesthetics, favorably emphasizing the natural structure of wood of various species.

In addition, such compositions form an additional and very strong protective film that enhances the strength, wear resistance and life cycle of wooden surfaces. Filling the pores, they prevent the decay and activity of bugs, bark beetles, and other pests. Such a finishing material is easy to apply, it is well leveled, it dries quickly. It is environmentally friendly, harmless to human health and practically odorless. All this makes acrylic coatings the undisputed leaders in the field of building and finishing materials intended for processing wooden surfaces and wood products.

A water-based acrylic wood varnish applied by a skillful hand not only gives the surface an aesthetic appearance, but also protects it from many adverse factors. Acting as a kind of “armor”, a water-based varnish for wood protects surfaces from moisture and atmospheric phenomena. It effectively protects the tree from pests and premature natural aging. Where can this finishing material be used, how to choose it correctly and how to work with it?

The technology for the production of acrylic paints and varnishes (LKM) is relatively young - it has been counting its history since 1952. Due to their properties, such compositions rapidly gained high popularity and wide distribution throughout the world. Today, this material for painting and protecting surfaces and objects made from various types of wood is used in a variety of fields and areas.

The composition of a water-based acrylic lacquer includes, as a rule, the following components and components:

- acrylic dispersion. A material based on a complex technology for processing essential elements of polymer resins - acrylic, cyanoacrylic or methacrylic acid;

- plasticizer. A substance that gives the varnish or paint optimal plasticity, the necessary consistency and proper binding properties;

- Antiseptic additives and impregnations. It is they that give the dispersion high protective properties, providing additional surface protection from mechanical influences, environmental influences and the creation of an additional laminating film.

All these components in various proportions are mixed on a water basis with a uniform degree of intensity. Since the acrylic varnish for wood at the output is a transparent and absolutely colorless liquid of a homogeneous consistency, a certain stage of production involves the addition of various coloring agents to its composition. This is done not only to ensure that the colorless dispersion has, for example, a white color or a glossy texture. Modern powder paint is able to form additional protection against adverse effects of various kinds.

In addition, today, in addition to resins, various components based on polyurethane are often added to the composition of water-based acrylic varnish for wood. Such coatings are called "two-component", and their ability to form a protective film and a decorative component significantly exceeds the capabilities and consumer properties of one-component water-based wood varnishes.

Main advantages

Gone are the days when compositions for coating wood products and surfaces left much to be desired in terms of their environmental performance and impact on human health. Unlike oil-based or purely chemical-based coatings, modern acrylic varnish or paint has a number of quite obvious and undeniable advantages. The main ones are the following:

- environmental friendliness, safety for health, no harmful emissions;

- high fire resistance and fire safety;

- immunity to moisture and to the effects of atmospheric phenomena, or temperature extremes;

- resistance to direct sunlight and ultraviolet;

- resistance to active chemical components and aggressive environments;

- good antiseptic properties that prevent the accumulation of dirt, formation or fungus;

- effective protection of wood from decay and pests;

- easy application, quick drying, unpretentiousness in personal care;

- durability and resistance to mechanical or impact loads;

- aesthetic appearance, a variety of textures, textures and colors.

Due to such high consumer and functional properties, the composition has a high versatility of application. With its help, you can solve a wide variety of tasks, perform both external and internal finishing work, applying it in various fields and areas. Such compositions are often used not only in the field of repair and construction, but also in art, for example.

Application specifics

Speaking about the areas of application of acrylic varnishes for wood, it is necessary to mention one more type of classification of this commodity group of coatings. The fact is that, according to the appearance of the final result, such compositions can be conditionally divided into three large groups:

- Glossy. The most popular type in the production of decorative work on the processing of parquet and other types of wooden floor coverings. Enhances the shine of polished wood. Often used to create a "mirror" floor effect. Often found in palaces, mansions, museums or luxury homes. Sometimes it is used to decorate objects and products made from various types of wood. Requires serious care and respect;

- Matte. A much more common type, the composition of which is arranged in such a way that the surface can acquire a wide variety of colors. In addition, matt acrylic lacquer successfully masks irregularities and defects in the coating, has higher wear resistance and unpretentiousness in personal care. It is much more durable than a glossy finish and gives the wood surface a certain or velvety feel;

- Semi-matte. It occupies an intermediate position between the two types listed above, combining the advantages of both. Finds the widest application in construction, when carrying out repair and finishing works, both internal and external.

Regardless of which of the above groups it belongs to, the finishing composition, in addition to its decorative abilities, has another important and useful property. It is able to penetrate deep into the pores of a wooden surface, giving it increased moisture resistance and significantly increasing its durability. That is why professionals prefer acrylic paintwork materials when compared with conventional, traditional paintwork materials.

Note! Since acrylic varnishes for wood are water-based, they should only be diluted with water! The use of drying oil, solvent and other paints and varnishes is unacceptable!

Applications

Due to their properties and the advantages that acrylic coatings have, which were discussed above, they have found application in a wide variety of fields and areas:

- construction and repair, protection of wooden structures;

- decoration of wooden surfaces and products;

- creation of interior design elements;

- internal and external finishing works.

Such paints and varnishes are actively used in suburban construction, in the processing of furniture or furnishings made of wood, for decorating facades or wall panels. The areas of application of finishing and decorative compositions based on acrylic resins are very wide and varied. Due to the ease of application, quick drying, high aesthetic properties, such compositions look much more preferable than oil paint. No wonder today these paintwork materials are successfully replacing it in the production of finishing or repair work. Moreover, they can handle not only wood surfaces and products.

Matte and glossy acrylic lacquer:

The unique characteristics of water-based acrylic coatings determine their wide distribution and high popularity. They give the surfaces a unique aesthetics, favorably emphasizing the natural structure of wood of various species.

In addition, such compositions form an additional and very strong protective film that enhances the strength, wear resistance and life cycle of wooden surfaces. Filling the pores, they prevent the decay and activity of bugs, bark beetles, and other pests. Such a finishing material is easy to apply, it is well leveled, it dries quickly. It is environmentally friendly, harmless to human health and practically odorless. All this makes acrylic coatings the undisputed leaders in the field of building and finishing materials intended for processing wooden surfaces and wood products.